The production of Leica watches

The production of Leica watches

January 19, 2024

One of a total of 45 individual screws that are being used within the L1 watch movement

The great love of detail is not only evident in the production of the calibers with patented push-crown, which Leica realises together with Lehman Präzision in the Black Forest; it is just as obvious in the photographs taken by Michael Agel at the factory. Rather than unemotionally documenting the technology, his images stir both the senses and the desire for a Leica timepiece. They reveal details of the steps that need to be taken, giving an idea of how much knowledge and skill is required to manufacture these pieces. In addition to the aforementioned, hand-wound watches, which are currently available in three versions, Leica have also introduced their first automatic watches with Swiss calibers.

LFI 1.2024+-

A detailed report about the ZM 11 and the very limited edition ZM 1 Gold Edition is found in issue 1/2024 of LFI. More

One of a total of 45 individual screws that are being used within the L1 watch movement

The L2's GMT-bridge, which comes from the galvanic coating process

A specialy developed diferential gear is used to provide an even closing and opening of the power-reserve indicator blades

The blades of the power reserve indicator being attached to the movement via a small screw

The ratchet wheel being checked for burrs happening during the manufacturing process. On the L1 and L2 models, it is part of the patented push-crown mechanism

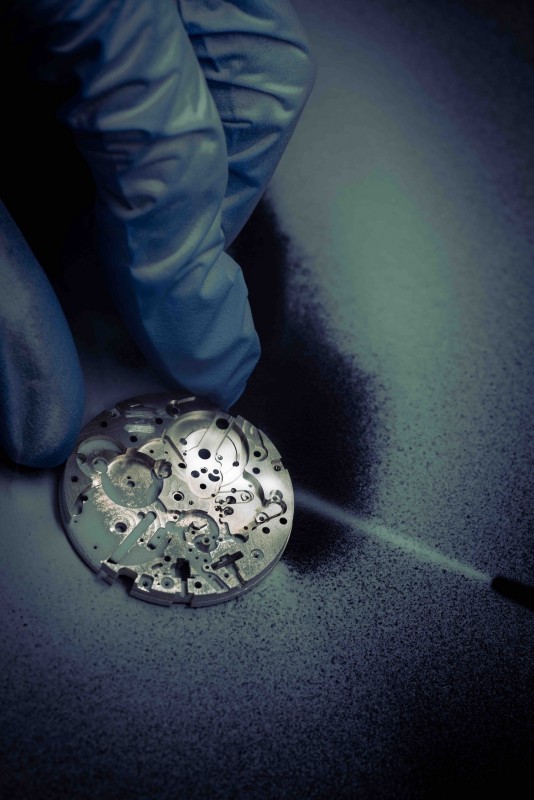

The base plate of the movement being sandblasted to give the surface a rugged finish

Individual indices being placed on the dial before being permanently affixed

Indices being milled from a brass plate

Individual indices lined up before being plated with rhodium

The small second hand being applied to the movement using a specialised tool